I-microscope ye-electron yokuskena yayisetyenziselwa ukujonga ukuphuka kokukhathala kunye nokuhlalutya indlela yokuphuka; Kwangaxeshanye, uvavanyo lokudinwa ukugoba lwenziwa kwisampulu ekhutshiweyo kumaqondo obushushu ahlukeneyo ukuthelekisa ubomi bokudinwa kwentsimbi yovavanyo kunye nangaphandle kwe-decarburization, kunye nokuhlalutya isiphumo sokususwa kwecarburization ekusebenzeni kokudinwa kwentsimbi yovavanyo. Iziphumo zibonisa ukuba, ngenxa yobukho ngaxeshanye be-oxidation kunye ne-decarburization kwinkqubo yokufudumeza, intsebenziswano phakathi kwezi zimbini, okukhokelela kubunzima bomaleko owenziwe ngokupheleleyo kunye nokukhula kobushushu bubonisa umkhwa wokunyuka kunye nokuncipha, Ubukhulu bomaleko we-decarburized ngokupheleleyo bufikelela kwixabiso eliphezulu le-120 μm kwi-750 ℃, kwaye ubukhulu bomgangatho owenziwe ngokupheleleyo bufikelela kwixabiso elincinci le-20 μm kwi-850 ℃, kunye nomda wokudinwa kwentsimbi yokuvavanya malunga ne-760 MPa, kwaye umthombo wokudinwa kokuqhekeka kwintsimbi yokuvavanya ngokuyininzi i-Al2O3 i-non-metallic inclusions; Ukuziphatha kwe-decarburization kunciphisa kakhulu ubomi bokudinwa kwentsimbi yovavanyo, kuchaphazela ukusebenza kokudinwa kwentsimbi yovavanyo, kokukhona ukuqina komgangatho we-decarburization, ubomi bokudinwa busezantsi. Ukuze kuncitshiswe impembelelo decarburization umaleko ekusebenzeni ukudinwa kwentsimbi yokuvavanya, ubushushu obufanelekileyo bonyango lobushushu bovavanyo lwentsimbi kufuneka lubekwe kwi-850 ℃.

Igiya yinxalenye ebalulekileyo yemoto, ngenxa yokusebenza ngesantya esiphezulu, inxalenye ye-meshing yomgangatho wegiya kufuneka ibe namandla aphezulu kunye nokuxhathisa kwe-abrasion, kwaye ingcambu yezinyo kufuneka ibe nokusebenza kakuhle kokugoba ngenxa yomthwalo ophindaphindiweyo ophindaphindiweyo, ukuze kuthintelwe iintanda ezikhokelela kwizinto eziphathekayo. ukwaphuka. Uphando lubonisa ukuba i-decarburization yinto ebalulekileyo echaphazela ukusebenza kokudinwa kwe-spin yezixhobo zentsimbi, kwaye ukugoba ukugoba ukusebenza sisalathiso esibalulekileyo somgangatho wemveliso, ngoko ke kuyafuneka ukuba ufunde indlela yokuziphatha kwe-decarburization kunye nokugoba ukudinwa kokusebenza kwemathiriyeli yovavanyo.

Kweli phepha, iziko unyango ubushushu kwi 20CrMnTi gear steel umphezulu decarburization uvavanyo, ukuhlalutya amaqondo obushushu ezahlukeneyo kuvavanyo metal decarburization umaleko ubunzulu umthetho otshintshayo; usebenzisa i-QBWP-6000J umatshini wokuvavanya ukudinwa kwe-beam elula kwi-test steel rotary bending ukudinwa uvavanyo, ukuzimisela kovavanyo lokudinwa kwensimbi, kwaye kwangaxeshanye ukuhlalutya ifuthe le-decarburization kwintsebenzo yokudinwa kwentsimbi yokuvavanya imveliso yokwenene yokuphucula. inkqubo yemveliso, ukuphucula umgangatho weemveliso kunye nokubonelela ngereferensi efanelekileyo. Uvavanyo lokudinwa kwensimbi lumiselwa ngumatshini wokuvavanya ukudinwa kwe-spin.

1. Izinto zokuvavanya kunye neendlela

Izinto zokuvavanya kwiyunithi yokubonelela nge-20CrMnTi yentsimbi yentsimbi, i-chemical composition ephambili njengoko kuboniswe kwiThebhile 1. Uvavanyo lwe-Decarburization: izinto zokuvavanya zicutshungulwa kwi-Ф8 mm × 12 mm ye-cylindrical specimen, umphezulu kufuneka ukhanye ngaphandle kwamabala. Iziko lonyango lobushushu lafudunyezwa ukuya kuma-675 ℃, 700 ℃, 725 ℃, 750 ℃, 800 ℃, 850 ℃, 900 ℃, 950 ℃, 1,000 ℃, kwaye nibambe iqondo lobushushu 1,000 ℃, emva koko lakhokelela emoyeni. Emva konyango lobushushu lomzekelo ngokuseta, ukusila kunye nokuguliswa, kunye ne-4% ye-nitric acid alcohol solution yokhukuliseko, ukusetyenziswa kwe-microscopy ye-metallurgical ukujonga umaleko we-steel decarburization, ukulinganisa ubunzulu be-decarburization layer kumaqondo okushisa ahlukeneyo. Uvavanyo lokudinwa kwe-Spin: izinto zovavanyo ngokweemfuno zokusetyenzwa kwamaqela amabini eesampuli zokudinwa kokugoba, iqela lokuqala alilwenzi uvavanyo lwe-decarburization, iqela lesibini lovavanyo lwe-decarburization kumaqondo obushushu ahlukeneyo. Ukusebenzisa i-spin yokugoba umatshini wokuvavanya ukukhathala, amaqela amabini ovavanyo lwensimbi yokuvavanya ukugoba ukukhathala, ukuzimisela umda wokudinwa kwamaqela amabini ensimbi yokuvavanya, ukuthelekisa ubomi bokukhathala kwamaqela amabini ovavanyo lwentsimbi, ukusetyenziswa kokuskena. I-electron microscope ukukhathala kokubona ukuphuka kwe-fracture, ukuhlalutya izizathu zokuphulwa komzekelo, ukuphonononga umphumo we-decarburization yeempawu zokudinwa kwentsimbi yokuvavanya.

Itheyibhile 1 Ukwakheka kweekhemikhali (iqhezu lobunzima) yentsimbi yovavanyo wt%

Impembelelo yobushushu bokufudumala kwi-decarburization

I-morphology yombutho we-decarburization phantsi kobushushu obuhlukeneyo bokufudumeza buboniswa kwi-Fig. xa iqondo lobushushu linyuka liye kuma-700 ℃, isampuli yomphezulu we-decarburization layer yaqala ukuvela, kuba umaleko obhityileyo we-ferrite decarburization; kunye neqondo lobushushu liyenyuka ukuya kwi-725 ℃, ubukhulu besampulu yomphezulu we-decarburization bonyuke kakhulu; 750 ℃ decarburization umaleko ubukhulu bufikelela kwixabiso layo eliphezulu, ngeli xesha, ingqolowa ferrite icace ngakumbi, irhabaxa; xa iqondo lobushushu linyuka ukuya kuma-800 ℃, ubungqingqwa bomaleko we-decarburization buqale ukuhla kakhulu, ubukhulu bawo buwele kwisiqingatha se-750 ℃; xa iqondo lobushushu liqhubeka nokunyuka ukuya kwi-850 ℃ kwaye ubukhulu be-decarburization buboniswe kwi-Fig. xa iqondo lobushushu liqhubeka nokunyuka ukuya kuma-850 ℃ nangaphezulu, uvavanyo lwentsimbi egcweleyo ye-decarburization umaleko ubukhulu buyaqhubeka nokuncipha, isiqingatha se-decarburization umaleko ubukhulu baqala ukunyuka ngokuthe ngcembe de yonke i-decarburization layer morphology yanyamalala yonke, isiqingatha se-decarburization layer morphology yacaca ngokuthe ngcembe. Kuyabonakala ukuba ubukhulu bomaleko we-decarburized ngokupheleleyo kunye nokwanda kobushushu bonyuswa kuqala kwaye buncitshiswe, isizathu salo mcimbi kungenxa yesampulu kwinkqubo yokufudumeza kwangaxeshanye i-oxidation kunye nokuziphatha kwe-decarburization, kuphela xa isantya se-decarburization sikhawuleza kunesantya se-oxidation siya kubonakala i-decarburization phenomenon. Ekuqaleni kokufudumeza, ubukhulu bomgangatho we-decarburized ngokupheleleyo buyanda ngokuthe ngcembe ngokunyuka kwamaqondo obushushu de ubungakanani bomgangatho ogqityiweyo ngokupheleleyo bufikelele kwixabiso eliphezulu, ngeli xesha ukuqhubeka nokunyusa ubushushu, isantya se-oxidation somzekelo sikhawuleza kunoko. ireyithi ye-decarburization, ethintela ukunyuka kwe-decarburized layer, ekhokelela kwindlela yokuhla. Ingabonwa ukuba, ngaphakathi koluhlu lwe-675 ~950 ℃, ixabiso lobunzima bomgangatho ogqityiweyo ngokupheleleyo kwi-750 ℃ lelona likhulu, kwaye ixabiso lobunzima bomgangatho owenziwe ngokupheleleyo kwi-850 ℃ lelona lincinci, ke ngoko, ubushushu bobushushu bovavanyo lwentsimbi bucetyiswa ukuba bube yi-850 ℃.

Fig.1 Histomorphology of decarburized layer of test steel egcinwe kumaqondo obushushu ahlukeneyo nge-1h.

Xa kuthelekiswa ne-semi-decarburized layer, ubukhulu be-decarburized layer inefuthe elibi kakhulu kwiipropathi zezinto eziphathekayo, kuya kunciphisa kakhulu iimpawu zomatshini wezinto eziphathekayo, ezinjengokunciphisa amandla, ukuqina, ukuxhathisa kunye nomda wokudinwa. , njl., kwaye ukwandise uvakalelo kwiintanda, ezichaphazela umgangatho we-welding kunye nokunye. Ke ngoko, ukulawula ubungqingqwa bomaleko we-decarburized ngokupheleleyo kubaluleke kakhulu ukuphucula ukusebenza kwemveliso. Umzobo wesi-2 ubonisa igophe eliguquguqukayo lobunzima bomaleko okhutshwe ngokupheleleyo kunye nobushushu, obonisa ukuguquguquka kobunzima bomaleko owenziwe ngokupheleleyo ngokucacileyo ngakumbi. Inokubonwa kumzobo ukuba ubukhulu bomaleko we-decarburized ngokupheleleyo bumalunga ne-34μm kwi-700℃; ngokunyuka kwamaqondo obushushu ukuya kwi-725 ℃, ubukhulu bomaleko we-decarburized ngokupheleleyo buyanda kakhulu ukuya kuma-86 μm, obungaphezulu kwamaxesha amabini obunzima bomaleko owenziwe ngokupheleleyo kwi-700 ℃; xa ubushushu bunyuswa ukuya ku-750 ℃, ubukhulu bomaleko we-decarburized ngokupheleleyo. njengoko iqondo lobushushu liqhubeka nokunyuka, ubukhulu bomaleko we-decarburized ngokupheleleyo buqala ukuhla ngokukhawuleza, ukuya kuma-70 μm kwi-800℃, kwaye ke ukuya kwixabiso elincinci malunga ne-20μm kwi-850℃.

Umzobo.2 Ukutyeba komaleko osuswe icarburized ngokupheleleyo kumaqondo obushushu ahlukeneyo

Impembelelo ye-decarburization ekusebenzeni kokudinwa kukugoba

Ukuze ufunde ifuthe le-decarburization kwiipropathi zokudinwa kwentsimbi yasentwasahlobo, amaqela amabini ovavanyo lokudinwa kokugoba lwenziwa, iqela lokuqala yayiluvavanyo lokudinwa ngokuthe ngqo ngaphandle kwe-decarburization, kwaye iqela lesibini yayiluvavanyo lokudinwa emva kwe-decarburization kuxinzelelo olufanayo. inqanaba (810 MPa), kunye nenkqubo ye-decarburization yabanjwa kwi-700-850 ℃ ye-1 h. Iqela lokuqala leesampulu liboniswa kwiThebhile 2, ubomi bokukhathala kwensimbi yasentwasahlobo.

Ubomi bokukhathala beqela lokuqala leesampuli luboniswe kwiThebhile 2. Njengoko kunokubonwa kwiThebhile 2, ngaphandle kwe-decarburization, insimbi yokuvavanya yayixhomekeke kuphela kwimijikelezo ye-107 kwi-810 MPa, kwaye akukho fracture eyenzekayo; xa inqanaba loxinzelelo lidlula i-830 MPa, ezinye zeesampuli zaqala ukuphuka; xa inqanaba loxinzelelo lidlula i-850 MPa, iisampuli zokukhathala zonke zaphuka.

Itheyibhile 2 Ubomi bokudinwa phantsi kwamanqanaba oxinzelelo ahlukeneyo (ngaphandle kwe-decarburization)

Ukuze unqume umda wokukhathala, indlela yeqela isetyenziselwa ukumisela umda wokukhathala wensimbi yokuvavanya, kwaye emva kokuhlalutya kwamanani edatha, umda wokukhathala wensimbi yokuvavanya malunga ne-760 MPa; ukuze kubonakaliswe ubomi bokukhathala kwensimbi yokuvavanya phantsi koxinzelelo oluhlukeneyo, i-curve ye-SN icwangciswe, njengoko kuboniswe kuMzobo 3. Njengoko kunokubonwa kwi-Figure 3, amanqanaba ahlukeneyo oxinzelelo ahambelana nobomi obukhathalayo obuhlukeneyo, xa ubomi bokukhathala kwe-7 , ehambelana nenani lemijikelezo ye-107, oku kuthetha ukuba i-specimen ephantsi kwezi meko idlula urhulumente, ixabiso elihambelanayo loxinzelelo linokuqikelelwa njengexabiso lamandla okukhathala, oko kukuthi, i-760 MPa. Ingabonwa ukuba i-S - N ijika ibalulekile ekuzimiseleni ubomi bokukhathala kwezinto eziphathekayo zinexabiso elibalulekileyo lokubhekisela.

Umzobo we-3 we-SN ijika lovavanyo lokudinwa kwentsimbi yokugoba

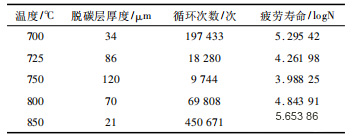

Ubomi bokukhathala kweqela lesibini leesampuli luboniswe kwiThebhile 3. Njengoko kunokubonwa kwiThebhile 3, emva kokuba intsimbi yokuvavanya i-decarburized kumaqondo okushisa ahlukeneyo, inani lemijikelezo liyancipha ngokucacileyo, kwaye lingaphezulu kwe-107, kwaye zonke imizekelo yokudinwa yaphuka, kwaye ubomi bokudinwa buyancipha kakhulu. Idityaniswe nobungqingqwa bomaleko we-decarburized kunye nejiko lokutshintsha ubushushu bunokubonwa, i-750 ℃ i-decarburized layer thickness yeyona inkulu, ihambelana nelona xabiso liphantsi lobomi bokudinwa. 850 ℃ decarburized umaleko ukutyeba yeyona incinci, ehambelana nexabiso lobomi ukudinwa liphezulu noko. Ingabonwa ukuba ukuziphatha kwe-decarburization kunciphisa kakhulu ukusebenza kokudinwa kwezinto, kwaye ubuninzi bomgangatho we-decarburized, buphantsi ubomi bokudinwa.

Itheyibhile 3 Ubomi bokudinwa kumaqondo obushushu ahlukeneyo e-decarburization (560 MPa)

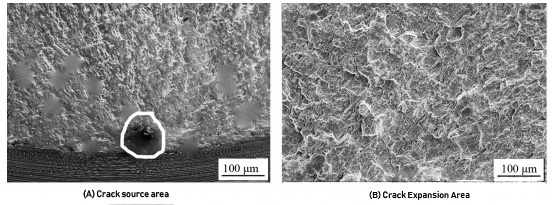

Ukudinwa kokwaphuka kwe-morphology yomzekelo kujongwe ngokuskena i-electron microscope, njengoko kubonisiwe kumfanekiso we-4. Umzobo 4(a) wendawo yomthombo wokuqhekeka, umzobo unokubonwa ngokucacileyo i-arc yokudinwa, ngokwe-arc yokudinwa ukufumana umthombo. ukukhathala, kunokubonwa, umthombo wokuqhekeka kwe "fish-eye" inclusions non-metallic inclusions, ukufakwa ngokulula ukubangela uxinzelelo loxinzelelo, okubangelwa ukuchithwa kokukhathala; Isazobe 4(b) semopholoji yokwandiswa kwendawo yokuqhekeka, inokubonwa imigca yokudinwa okucacileyo, yayisasazeke njengomlambo, iyinxalenye yokwaphuka kwe-quasi-dissociative, kunye neentanda ezandayo, ekugqibeleni zikhokelela ekuqhekekeni. Umzobo 4(b) ubonisa i-morphology yendawo yokwandiswa kwee-crack, ukudinwa okucacileyo kunokubonwa, ngendlela yokusabalalisa okufana nomlambo, okuyingxenye ye-quasi-dissociative fracture, kunye nokwandiswa okuqhubekayo kweentanda, ekugqibeleni kukhokelela ekuqhekekeni. .

Uhlalutyo lokuqhekeka kokukhathala

Umzobo we-4 SEM i-morphology ye-fatigue fracture surface yentsimbi yokulinga

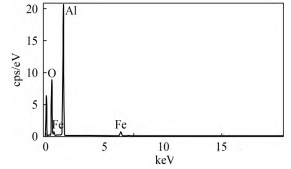

Ukuze unqume uhlobo lokubandakanywa kwi-Fig. 4, uhlalutyo lokuqulunqwa kwe-energy spectrum lwenziwa, kwaye iziphumo ziboniswa kwi-Fig. ngowona mthombo uphambili wokuqhekeka okubangelwa yi-inclusions cracking.

Umzobo we-5 I-Spectroscopy yamandla we-Non-metallic Inclusions

Qukumbela

(1) Ukubeka ubushushu bokufudumala kwi-850 ℃ kuya kunciphisa ubukhulu bomgangatho owenziwe nge-decarburized ukunciphisa umphumo ekusebenzeni kokukhathala.

( 2) Umda wokukhathala wokuvavanya ukugoba kwentsimbi yi-760 MPa.

( 3 ) Uvavanyo lwensimbi yokuvavanya kwi-non-metallic inclusions, ngokukodwa umxube we-Al2O3.

(4) i-decarburization inciphisa kakhulu ubomi bokudinwa kwentsimbi yovavanyo, ukutyeba komgangatho we-decarburization, ubomi bokudinwa busezantsi.

Ixesha lokuposa: Jun-21-2024